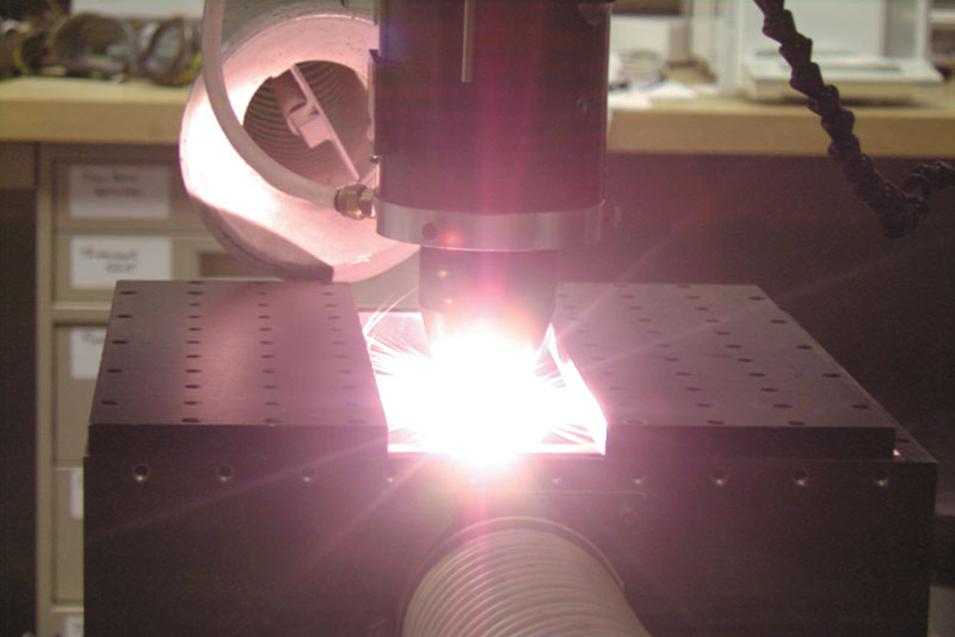

In the manufacturing industry, drilling with lasers is becoming more common than using sharpened steel. Lasers can be used to create small holes in metals or difficult designs. Depending on the laser type used, holes can be made as small as 10 micrometers.

A laser can be used to make holes in different sizes. While other drills would need to be modified to make larger holes, a laser does not require this change. This reduces the time required. You can get the services of laser drilling at www.protolase.com.

Image Source: Google

There are two types of laser drilling, percussion holds drilling and trepanning. Multiple pulses of laser are used in percussion drilling to achieve the desired results. This technique is used often to create guide and filter vanes. Trepanning is a technique that creates large holes in the material. This allows you to maintain consistency even with complex hole shapes and reduces the hole's taper.

Many manufacturing companies have adopted the laser drill in recent years because of the lower cost and wider applications. Many companies find the simplicity of drilling appealing, with only one laser required for multiple jobs.

Additionally, only one drill needs to be purchased over the course of one's life due to non-contact wear.

Laser drills are now more widely used, which has resulted in greater complexity and a shorter production time. Laser drills are also less expensive and require little maintenance.